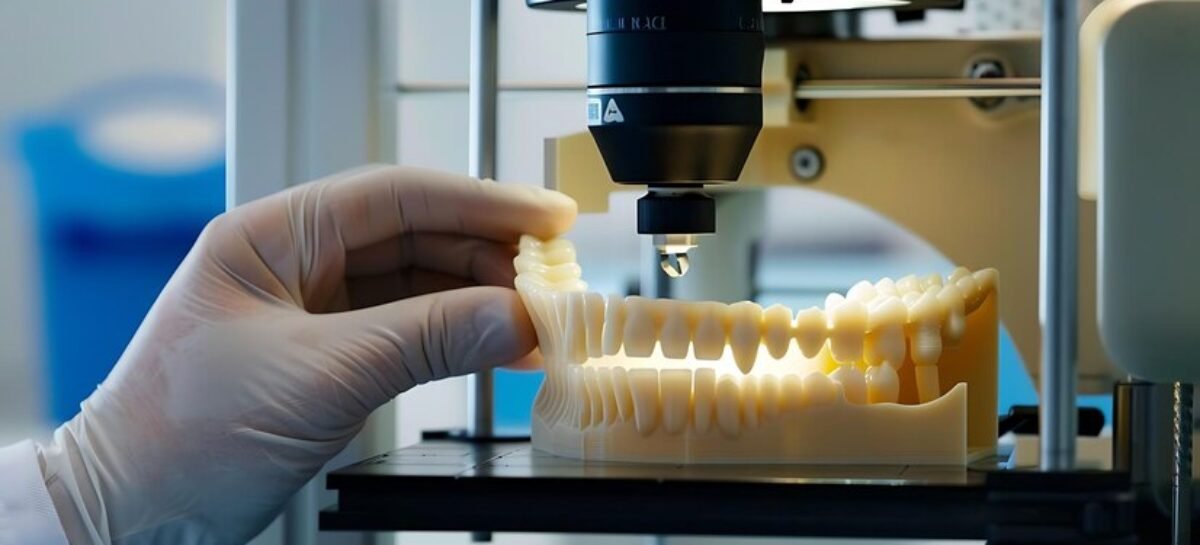

You can work with a dental lab to produce prototypes and precise crowns, bridges, dentures, aligners, and other orthodontic devices. The labs often invest in state-of-the-art equipment, such as 3D printers, innovative resins, and modern techniques to create high-quality products. Using 3D printers also results in faster turnaround times, industry-leading strength and accuracy, and cost reduction. Here’s how 3D printing can help with dental laboratory work:

Speed Up Fabrications

Dental laboratories fabricate many products, from retainers to surgical guides, anatomical models, and casting patterns. They can use various equipment, including specialized 3D printers, that offer faster prototyping and production. 3D printers reduce the time spent molding and casting dental products using traditional processes. The printers produce more accurate results, reducing human error and post-processing steps. Increased precision results in intricate designs that meet specific needs, including complex dental restorations.

Faster turnaround times allow the dental lab to produce more batches of prosthetics and devices and shorten delays. The dental impressions and fabrication information are saved in the lab’s software, allowing for rapid adjustments. Modern printers may feature advanced technologies, such as artificial intelligence and machine learning, that help to improve precision and efficiency. Lab technicians can review fabrication instructions, use in-built suggestions, and track production. The printers also produce bridges, crowns, and aligners with dimensions that frequently fit properly the first time, reducing the need for adjustments.

Support More Applications

Dental laboratories use 3D printers to provide a wide range of devices, from trays and smile shapers to procedural aids. Whether your clinic provides dentures, partials, or orthodontic splints and nightguards, the printers should accommodate all such productions. They use sophisticated software and advanced technology that supports various resins and dental applications. 3D printers can work with IPS Emax, PFMs, Zirconia, and other durable resins used to produce dentures, mouthguards, and orthodontics. The printers may produce snap-on smiles, clear aligners, and other devices featuring using flexible materials.

Third-party laboratories usually hire experienced technicians trained in the latest fabrication technologies, techniques, materials, and standards. They work with resins, ceramics, metal alloys, and other materials to produce durable devices that fit as intended. You can partner with the same lab for traditional metal and ceramic dentures or clear aligners and other transparent options. The labs also offer services for various dental applications, from temporary crowns to permanent restorations. 3D printing also allows the production of customized products tailored to your client’s unique anatomy and needs.

Improves Patient Experience

3D printers produce dental implants, aligners, and devices that fit the patients and provide increased comfort. Fast production and the reduced likelihood of time-consuming realignments could lead to fewer visits and overall satisfaction with the treatment experience. Labs can help you determine the ideal material for the patient and dental device. Resins like IPS Emax are appropriate for veneers, inlays, onlays, and implant-supported hybrid abutments and crowns. They’re also used for three-unit bridges up to the second premolars. Dental laboratories also feature other advanced equipment and technologies, including CAD and CAM systems that produce precise milling.

3D printing and other modern technologies work to lessen the need for labor-intensive manual work and waste production. Faster turnaround times also allow the lab to serve more clients, which may help them afford higher-quality machinery and materials. A result of using advanced practices and technology is that labs can provide for more patients without sacrificing the quality of their products. 3D printing also relies on intraoral scanning techniques, which are comfortable and produce more accurate impressions required for true-to-design end products.

Speak to an Experienced Dental Lab Today

Dental laboratories use various equipment, including 3D printers, that produce more precise orthodontics and devices in a shorter amount of time. You can partner with a lab to outsource fabrications for dental devices that need high precision and speedy production. Speak to a dental lab today to find out more about what you can achieve with 3D printing.